Yeah, it’s not just “fake wood”

Let’s start with something simple.

You ever walk through a furniture store… touched a table… and think, “Wait—this ain’t real wood?”

But it looks like wood. Feels like wood. Costs less than solid wood. So what gives?

That, my friend, is manufactured wood. And it’s not the enemy. It’s kinda brilliant.

Let’s talk about it. Let’s break it down like a carpenter with a brand-new saw.

So… What Is Manufactured Wood?

Alright. Let’s be real.

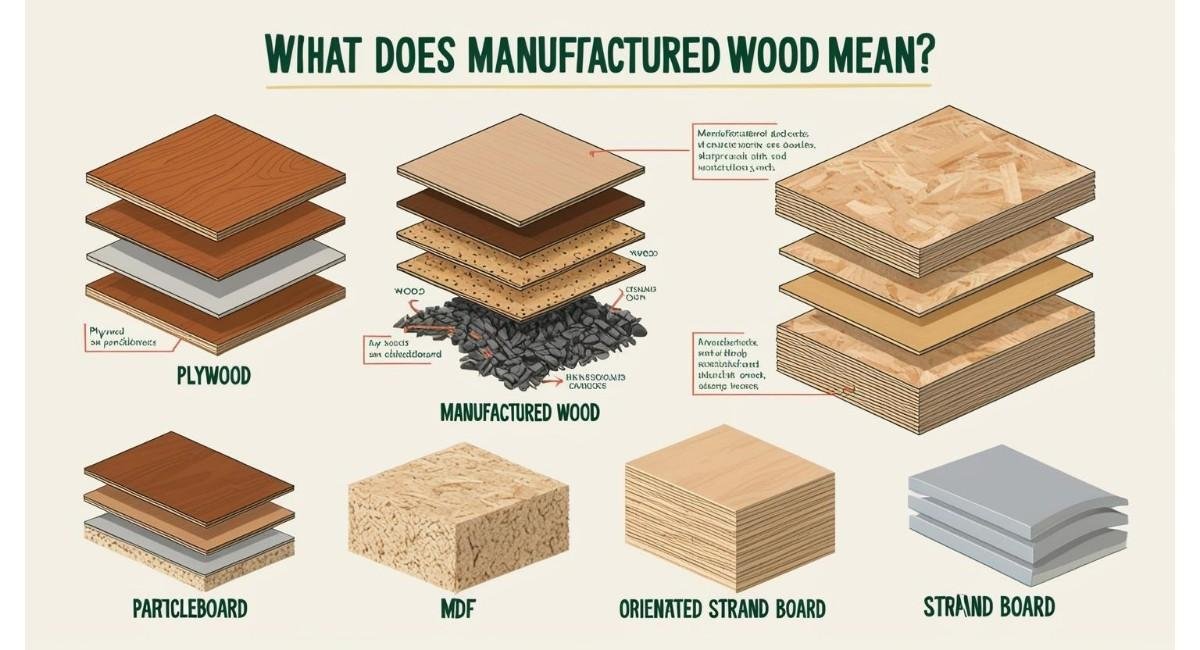

Manufactured wood is real wood. But it’s not solid wood. It’s been chopped, reassembled, pressed, and glued into new forms.

Think of it like a wood remix.

It’s made using leftover wood particles, fibers, veneers, or strands. Then those are bonded together with adhesives under heat and pressure. What comes out? Strong. Smooth. Uniform panels or boards.

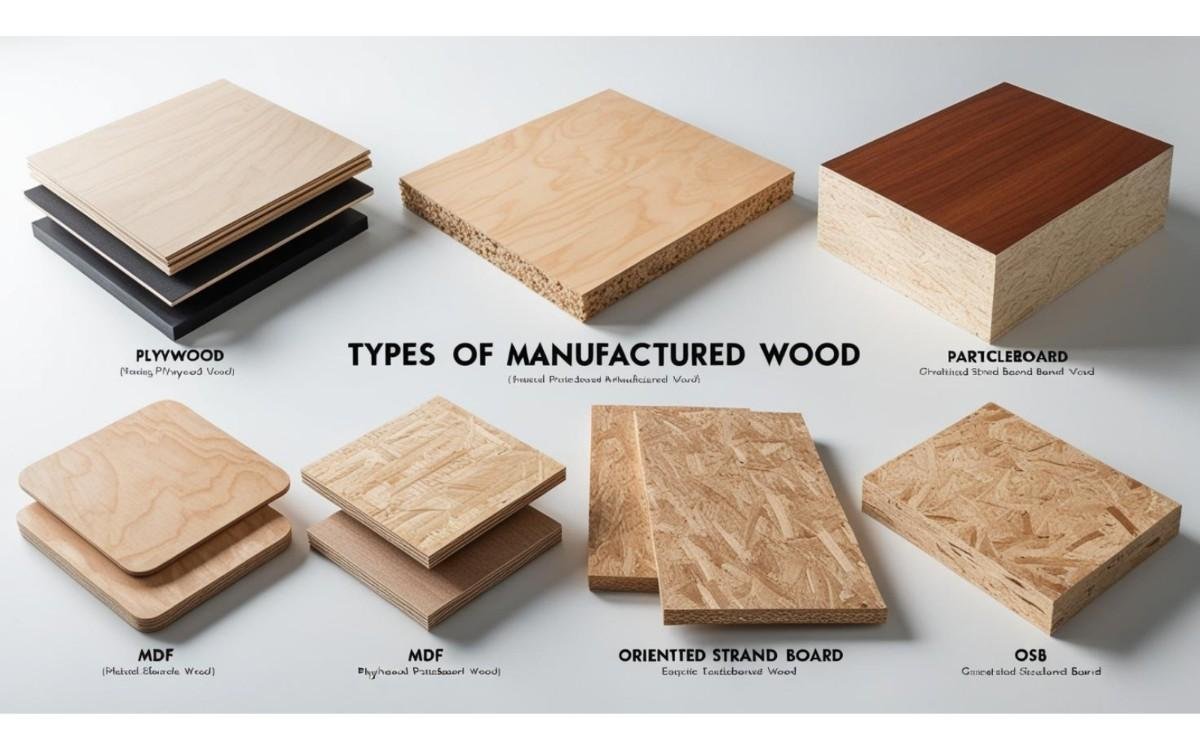

We’re talking stuff like:

- Plywood

- MDF (Medium Density Fiberboard)

- Particleboard

- OSB (Oriented Strand Board)

- Laminated Veneer Lumber (LVL)

And that’s just scratching the surface.

The Roots: Why Manufactured Wood Even Exists

Let’s rewind for a second.

Old-school homes used solid wood. Big beams. Chunky boards. But forests? They’re not infinite.

So smart folks started thinking—what if we used every part of the log? Every chip. Every splinter.

Boom. Manufactured wood was born. It reduced waste. Saved money. Made building faster and more efficient.

Even the top wood products manufacturers jumped in.

Now? It’s everywhere.

Why Is Everyone Using It?

Simple. It’s reliable. Versatile. And cost-effective.

Here’s what makes manufactured wood a crowd favorite:

- Stable: Doesn’t warp or shrink like solid wood

- Affordable: Way cheaper than premium hardwood

- Eco-Friendly: Uses recycled wood parts

- Easy to Work With: Uniform structure = smoother cuts

- Massive Variety: From floors to furniture to beams

Even major lumber manufacturers and engineered lumber products companies base their entire businesses around this stuff.

So yeah. It’s a big deal.

Let’s name-drop a little.

1. Plywood

Thin sheets of wood veneer, stacked in layers and glued. Super strong. Great for floors, roofs, and walls.

2. MDF (Medium-Density Fiberboard)

Wood fibers, compressed with resin. Smooth surface. Great for painting. A favorite among cabinet makers.

3. Particleboard

Made from wood chips and sawdust. Cheap. Lightweight. Often used for IKEA-type furniture.

4. OSB (Oriented Strand Board)

Large wood strands layered in specific directions. Common in subfloors and sheathing.

5. LVL (Laminated Veneer Lumber)

Thin veneers glued together in the same direction. Used in framing. You’ll find it with top-engineered wood lumber and glulam manufacturers.

Engineered Lumber: The Strong Sibling

Let’s talk heavy-duty.

Engineered wood gets even stronger when it’s used for structural stuff. Think beams, joists, and rafters.

These aren’t just planks. They’re the backbone of buildings.

If you’re in construction or renovation, you’ve seen:

- Engineered wood beam: Supports heavy loads. Looks like a wooden sandwich.

- Engineered wood joists: These long, lightweight planks go between walls and floors. Super precise.

- Engineered wood rafters: Supporting roof structures. Straight and strong.

It’s not about looks here. It’s about muscle.

And trust me, when you’re Googling “lumber manufacturers near me” for your next big project—these are the kinds of products you’ll be comparing.

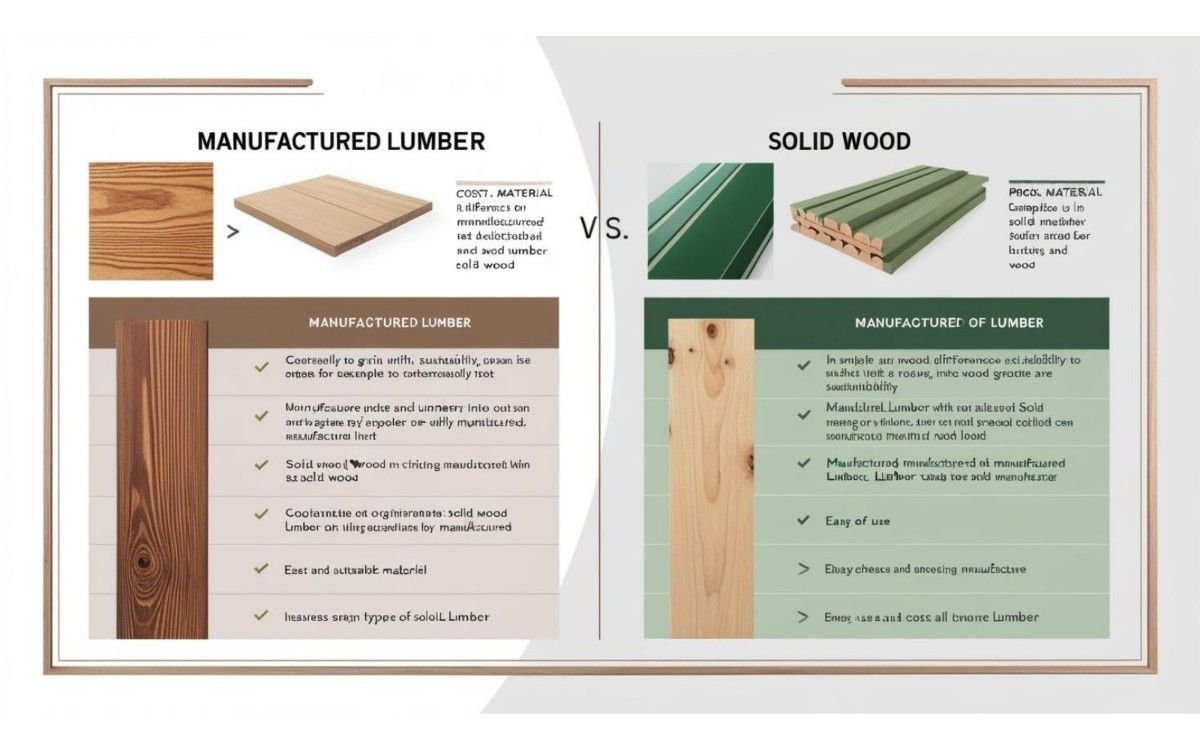

Manufactured Lumber vs. Solid Wood – Let’s Compare

Let’s clear this up.

| Feature | Manufactured Wood | Solid Wood |

| Price | Lower | Higher |

| Stability | Very stable | Can warp/shrink |

| Looks | Uniform | Natural grain |

| Strength | Very high (when engineered) | Depends on species |

| Eco-Friendly | High | Depends on sourcing |

| Weight | Often lighter | Heavier |

So is manufactured lumber worse? Nope. Just different.

You just gotta use the right wood for the right job.

The Making of Manufactured Wood – Quick Peek

Curious how it’s made? Here’s the short version:

- Raw wood is chipped, sliced, or peeled

- Drying happens in massive kilns

- Glue/resin gets added

- The mix is pressed under heat and pressure

- Boards are cut, cooled, and cured

- Final touches—laminating, sanding, trimming

Big machines. Big results. And behind it all? Teams from lumber manufacturers, engineered wood lumber mills, and wood products manufacturers doing the real work.

Story Time: My MDF Bookshelf

I gotta tell you.

I once bought this sleek little MDF bookshelf. Thought it was solid oak. Fooled me well.

Moved it three times. Held a ridiculous number of books. No warping. No cracks. Nothing.

And that’s the beauty of manufactured wood. It gets the job done—without shouting about it.

It just… works.

Who Makes This Stuff?

Oh, there’s a whole world behind your furniture.

Some of the biggest names in glulam manufacturers, engineered lumber products, and wood products manufacturers are in the U.S., Canada, Germany, and even Southeast Asia.

They produce it in massive plants. With machines the size of houses.

Glulam, short for glue-laminated timber, is another awesome type—used in long, curved beams in architecture. Stylish and strong.

These aren’t mom-and-pop shops. These are precision-focused, massive-scale producers.

And when you type “lumber manufacturers near me” on Google? You’re stepping into that same world.

The Green Side of Manufactured Wood

Yep, we’re going there.

Manufactured wood gets eco-points. Why?

- It uses waste material

- It maximizes every log

- It reduces the demand for old-growth solid timber

- Many use low-VOC adhesives

- Some even qualify for LEED points (green building)

Sure, not all are perfect. But when you buy from certified engineered wood lumber brands or mass timber producers, you support greener buildings.

Win-win.

What Should You Use Manufactured Wood For?

Honestly? Almost everything.

Here’s where it shines:

- Cabinets & Shelving: MDF all day.

- Subflooring: OSB or plywood—strong and steady.

- Roof Framing: Engineered wood rafters = straight as a ruler.

- Beams & Joists: Go with engineered wood joists or LVL beams.

- Furniture: Particleboard, MDF, or plywood—cost-friendly and stylish.

Just make sure it fits your purpose. Some types don’t love moisture. Some aren’t great outdoors.

But indoors? It’s gold.

Real Talk: Is It “Fake”?

Let’s squash this now.

Nope. Manufactured wood ain’t fake.

It’s real wood. Just processed, improved, and engineered.

Would you call a diamond from a lab “fake”? (Okay, maybe, but you get what I mean.)

The point is—this stuff’s made to perform. And in many ways? It beats traditional solid lumber.

The Future of Wood Is… Manufactured?

Totally.

With sustainability on everyone’s mind, manufactured wood is leading the charge. Less waste. Less deforestation. Smart design.

New tech is coming, too:

- Biodegradable resins

- Smarter presses

- Higher strength-to-weight ratios

- AI-optimized cutting and bonding

Companies are pushing the limits. Builders are trusting it. Homeowners are embracing it.

So yeah, the future looks woodsy. But smarter.

Final Thoughts – What Manufactured Wood Means

It means progress.

It means using more of what nature gives us—without taking more than we should.

It means buildings that last longer. Floors that stay flat. Shelves that don’t wobble.

It means a new kind of wood. One that’s part machine, part tree, part genius.

So next time someone says, “That ain’t real wood…” you’ll know better.

Because now, you know what manufactured wood means.